Food Safety. It’s a frequent topic in the news and food safety concerns can be a nightmare for food processors. According to the FDA, “About 48 million people (1 in 6 Americans) get sick, 128,000 are hospitalized, and 3,000 die each year from foodborne diseases.” Foodborne illness is largely preventable. Identifying one preventable contributor, the U.S. Food and Drug Administration reported that airborne contamination is a cause of pathogenic food contamination.

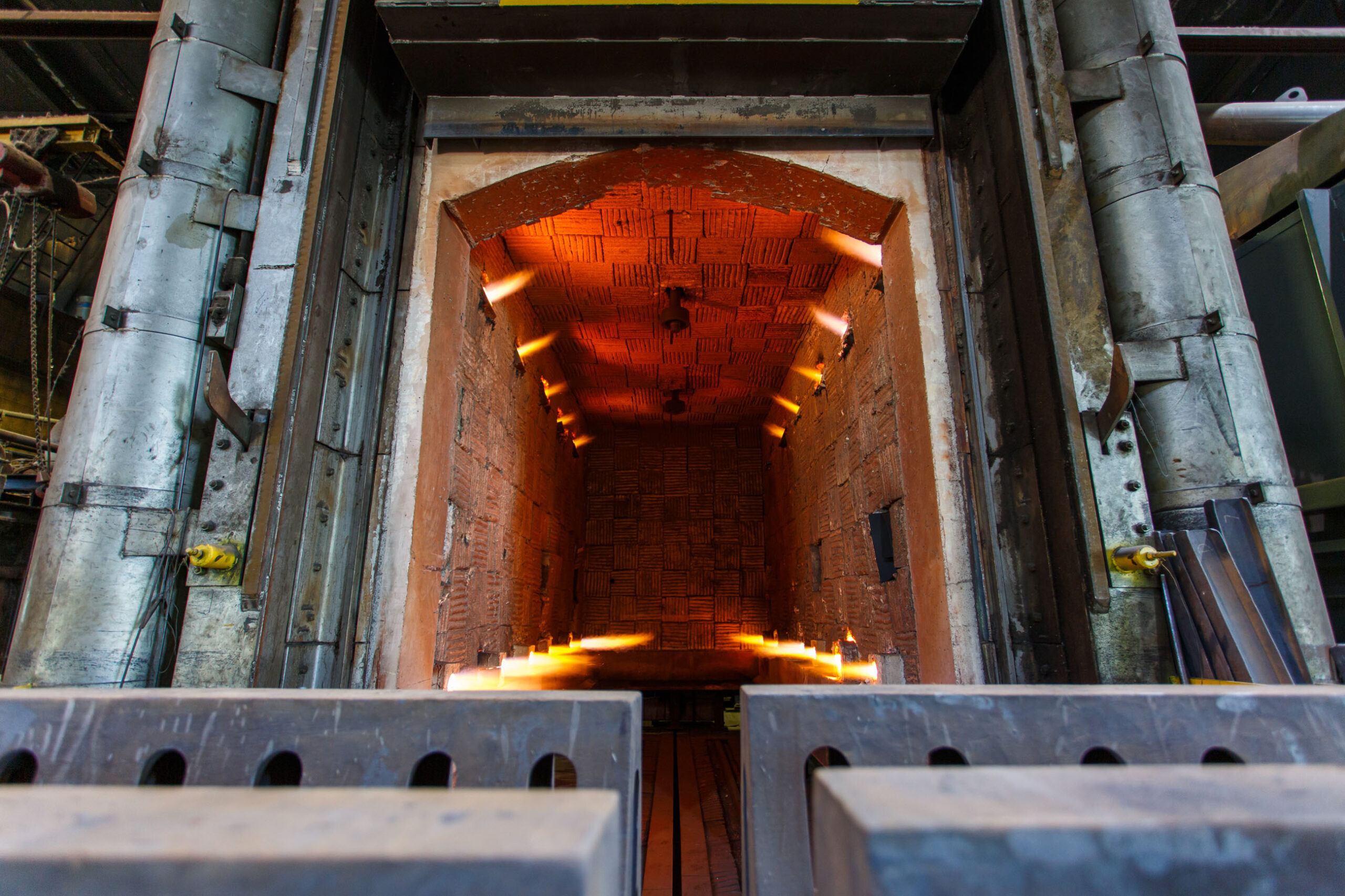

Food processing, including dairy, meat & cheese processing and ready-to-eat (RTE) food preparation requires hygienic air handling as a critical element of the food processing environment.

Too often, the focus of engineering is concentrated on the hygienic air handler with insufficient consideration given to the air delivery system. To create a sanitary process, hygienic duct design and fabrication, duct being the air delivery system, is often required.

For the “food safe design” of your facility, consider the following regulatory and safety considerations, as well as related ductwork design elements to help you make informed decisions.

Currently, the food processing industry is undergoing a shift from focusing on contamination response to contamination prevention. In 2011, the FDA Food Safety Modernization Act (FSMA) was signed into law.

The FSMA Final Rule for Preventive Controls for Human Food went into effect in 2015. The rule requires food facilities to have a food safety plan in place that includes an analysis of hazards and risk-based preventive controls to minimize or prevent the defined hazards.

The FDA developed Guidance Documents for the development of safety plans including, Control of Listeria Monocytogenes in Ready-To-Eat Foods. Consider this passage from that Guidance Document;

“We recommend that you design and construct the plant so that walls, ceilings, windows, doors, floors, drains, and overhead fixtures (e.g. pipes, air vents and lights) in areas where RTE foods are processed and exposed resist deterioration by product or cleaning chemicals and prevent condensate buildup and harborage of microorganisms,”

From the same FDA Guidance Document, the total hygienic and environmental impact of the airstream is further highlighted:

“We recommend that you design the air flow in your plant to maintain positive air pressure on the RTE side of the operation relative to the “raw” side (i.e. maintain higher air pressures in RTE areas and lower air pressure in areas where unprocessed (“raw”) foods are handled). We recommend that you consider the room temperature and the impact of airflow on controlling condensation in the plant. We also recommend that you consult individuals with appropriate engineering skills…”

If you are considering investing in a hygienic air handling and hygienic duct system, it’s important to consider all the options that are available.

We suggest starting by reviewing your environmental conditions and your wash down procedures when evaluating what types of ductwork you may need. Establish your own set of needs based on each area or zone. For instance, ductwork within cold storage areas could be considered a “low-care” area versus a food processing room which would likely be considered a “high care” area. Once you have the level of concern determined, you should work with your mechanical contractor to discuss options available to meet your needs.

Below are some areas where you can find variation in duct fabrication:

- Material: Stainless steel is the go-to choice of material in hygienic duct solutions. Standard offerings can feature either a 304 grade or a 316 grade stainless steel. 316 is generally more expensive. Based on you own set of needs, particularly make-up of food products or wash down chemicals, the 316 stainless steel premium for the inclusion of molybdenum (added to 316 stainless steel for corrosion resistance to chlorides) may provide a substantial value for your operations.

- Welds: Consider the “catch points”. Catch points are any projection into the air space where particles can be trapped, and thus causing a buildup of material that could lead to contamination. This is where the “harborage of microorganisms, referenced by the FDA, exist within ductwork. To eliminate “catch points”, one needs to define how smooth is smooth enough and whether the exterior of hygienic ducts surfaces should be subject to the same degree of cleanliness of design as the interior surfaces.

For these concerns, TIG welded duct (smoother, more expensive) vs. MIG welded duct is a decision worthy of consideration, as is the degree of cleaning and polishing of the welds. Duct manufacturers truly devoted to hygienic considerations invest in automated seam welding equipment which produces consistent, even longitudinal welds in formed ductwork.

If you are evaluating mechanical contractors to help with your hygienic ductwork needs, consider the following:

- What standards and levels of hygienic duct do they fabricate?

- Can they provide you physical samples of their product options?

- Can they provide customer references?

- Ask whether they used automation in weld processes to ensure consistency of welds in their duct.

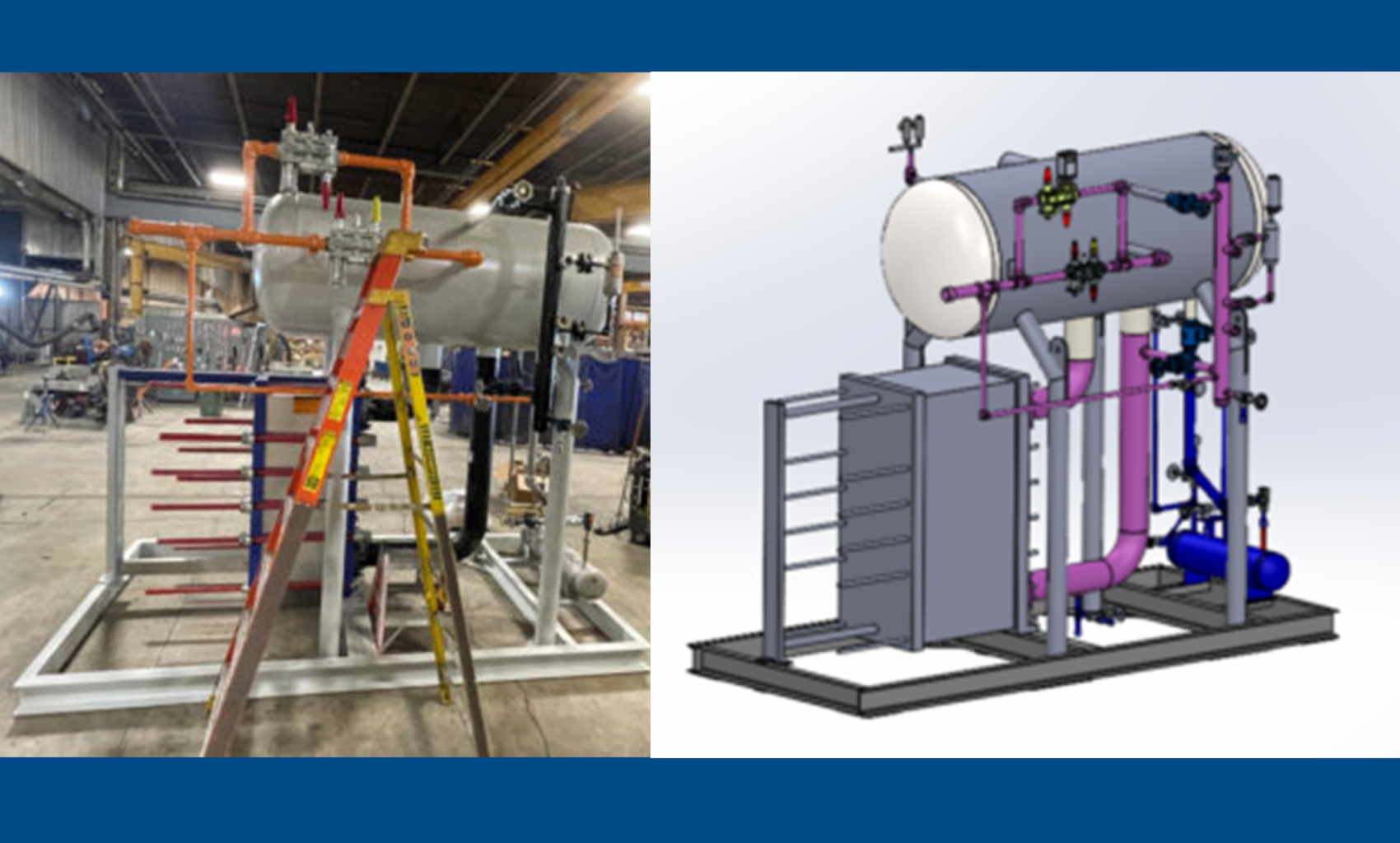

Overall, hygienic duct solutions need to be fabricated with material that is non-corrosive and cleanable. It needs to be designed with access points allowing for inspection and cleaning. Its very construction should minimize catch points to the degree required by the application.

Bassett Mechanical offers different hygienic ductwork solutions, custom finishes, sealed insulation options and hygienic metal fabrication that go far beyond hastily assembled duct.