For over 85 years, Bassett Mechanical has been a cornerstone of the mechanical contracting industry, evolving into a comprehensive solutions provider. Our journey into providing our refrigeration customers with solutions took a significant leap in 1979 when we began manufacturing ASME pressure vessels for ammonia refrigeration systems, laying the groundwork for decades of innovation, investment, and growth. Over the next decade, we honed our expertise, refining our processes and expanding our capabilities in response to industry needs.

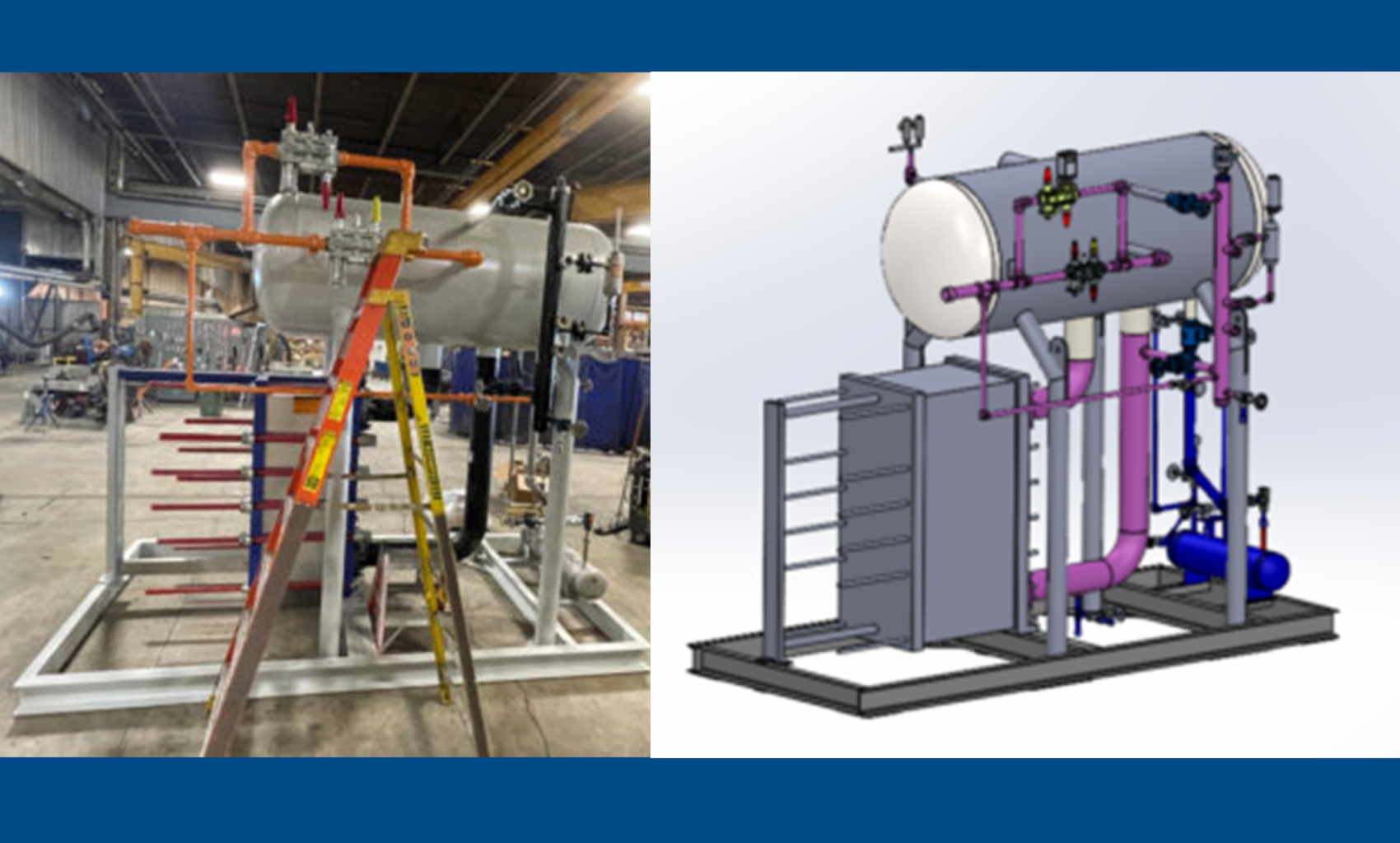

By 1992, our commitment to excellence led to the official registration of Thermatech. Thermatech quickly became an important and growing part of our business, reflecting its core focus on pressure vessels related to cooling equipment, chillers, and advanced thermal solutions. From the outset, Thermatech specialized in manufacturing ammonia-based chiller packages, reinforcing our long-standing reputation for quality and reliability in refrigeration.

One of Thermatech’s early ventures outside of the refrigeration industry was the production of Saturation Diving Chamber systems that enable divers to remain submerged for extended periods. This unique product demonstrated our advanced engineering capabilities, high level of craftsmanship, and adaptability in pressure vessel fabrication. However, as shipbuilders began integrating dive chambers directly into their new vessel designs, the demand for standalone chambers declined, prompting Thermatech to strategically pivot towards other refrigeration and cooling solutions while also growing the focus on pressure vessels for a wider range of applications and industries.

As we expanded into new markets, our pressure vessel business saw significant growth. To keep up with demand and manage our costs, we strategically invested in CNC cutting equipment, allowing us to produce pressure vessels more economically by reducing the manual labor associated with cutting plate steel and heads with penetrations, bevels, and layout lines. During that time, we also invested in a larger roll that allowed us to produce most pressure vessel shells in-house, ranging from 1 ¼” thick and up to 12 ft in diameter.

Thermatech has maintained a steadfast commitment to innovation and excellence in metal fabrication throughout its decades of strategic evolution. This enduring history, marked by the production of over 14,000 vessels since our first small refrigeration unit in 1979, is built upon the foundation of our highly skilled associates’ commitment to delivering on time with a high level of quality. Our journey has seen us expand our expertise to craft a diverse range of high-quality thermal solutions and vessels for various industries, now reaching impressive dimensions of up to 16′ in diameter, 180′ in length, and 5” in thickness and a wide range of specialty alloys. This growth reflects our unwavering dedication to quality, adaptability, and technical excellence.

Investing in Excellence: A Timeline of Technological Advancement

Our commitment to providing superior pressure vessels is evident in our ongoing investment in state-of-the-art equipment. Key milestones in our technological evolution include:

- Start-up (1979 -1997): Registered our first ASME Refrigeration Vessel with the National Board in 1979 and welded vessels together in a 2-stall garage utilizing cherry pickers and floor jacks. A roll, press break, and plasma table were used to complete the required components, but they were limited to thinner and smaller vessels.

- Early Expansion (1997-2012): Moved to our then 268,000 sq. ft. manufacturing facility in 1997 and expanded our footprint and offerings. Invested in press brakes, blast, and paint booth, weld positioners, and sub-arc welding equipment, significantly expanding our ability to handle larger and thicker materials.

- Modernization and Growth (2012 -Present): Consistent investments in advanced manufacturing equipment and facility layout have driven continued improvements in efficiency and quality. During this period, we expanded our facility from 268,000 sq. ft. to over 300,000 sq. ft. to accommodate growing operations and technological advancements. Key upgrades include additional overhead cranes, advanced multi-process welding machines, adjustable weld positioners, a CNC Structural Profiler, and a CNC Pipe Profiler. We also implemented a comprehensive digital workflow across our fabrication shop, utilizing iPads at workstations and automating material and welder traceability.

More Than Just Metal: Comprehensive Fabrication Solutions

Bassett Mechanical and Thermatech offer a comprehensive suite of metal fabrication services beyond pressure vessels, including:

- Advanced Pipe Fabrication: CNC cut parts, multi-process welding, dedicated Certified Welding Inspectors, real-time production tracking.

- Precision Laser Cutting: Delivering high accuracy and speed for various materials and thicknesses.

- Custom OEM Components and Sub-Assemblies: Tailored solutions for diverse manufacturing needs.

- Structural Steel Fabrication: Providing robust and reliable structural components, including ladders, large equipment platforms, and handrails.

- Hygienic Duct Solutions: Fully welded stainless steel fabrication for industries with stringent cleanliness standards, such as food processing.

- Comprehensive Sheet Metal Fabrication: Building on Bassett Mechanical’s long history in sheet metal work, including double wall and insulation/cladded systems.

Quality You Can Trust: Certifications and Expertise

Our commitment to quality is unwavering. Bassett’s manufacturing facility is ISO 9001 certified, and our skilled workforce includes a significant number of certified welders and fabricators. This dedication to industry standards ensures that every project meets the highest levels of quality, safety, and compliance.

Serving Diverse Industries

Thermatech proudly serves a wide range of industries, including:

- Food Processing

- Energy

- Construction

- Marine

- Manufacturing

- Paper

Our experience across these diverse sectors demonstrates the versatility and reliability of our metal fabrication capabilities.

Partner with Bassett Mechanical for Your Pressure Vessel Needs

The journey of Thermatech and metal fabrication at Bassett Mechanical, beginning with our entry into refrigeration vessel manufacturing in 1979, is a testament to our enduring commitment to innovation, quality, and customer satisfaction. From pioneering ammonia-based chiller packages and navigating early market challenges to our current status as a leading pressure vessel and thermal solutions provider, we have consistently invested in technology and talent to meet the market’s evolving needs.

Ready to experience the Bassett Mechanical difference? Contact us today to discuss your pressure vessel fabrication requirements and discover how our expertise can help you achieve your project goals.