If only there was an easy button to determine the right refrigerant for your system.

If only there was an easy button to determine the right refrigerant for your system.

CO2 and ammonia are some of the earliest refrigerants and share some environmentally friendly characteristics. Both are very low in ozone depletion and global warming potential. The use of these natural refrigerants has grown as synthetic alternatives (CFC’s, HCFC’s, HFC’s ) have proven to drive less desirable environmental consequences.

The latest wave of synthetic refrigerants, HFO’s, have uncertain long-term consequences and regulatory hurdles in part due to the formation of TFA (a long-lived acid that can accumulate in bodies of water) as they break down in the atmosphere. Studies relating to the long-term effects of HFO’s and TFA are underway in Germany and Norway.

It can be concluded that CO2 and ammonia are good, long-term, sustainable and “green” refrigerant choices, both being particularly efficient for low-temperature refrigeration. But which is better for me and my unique system? In most industrial refrigeration systems, the choice is between CO2 or ammonia or a combination CO2/ammonia cascade system. To answer which of these three is best for you requires a review of several factors.

IS THIS A BRAND NEW SYSTEM OR AN ADDITION TO AN EXISTING SYSTEM?

If your project is an addition to an existing ammonia system, the facility is likely already very familiar with the plusses and minuses of operating an ammonia system. The power bills reflect the inherent energy efficiency of an ammonia system. The safety considerations and the regulatory compliance needs of an ammonia system are a part of current operating procedures. The unique service aspects of an ammonia refrigeration system have been addressed and are part of the day-to-day activities. Adding additional ammonia service is frequently the easiest, smartest, and lowest risk alternative.

Processors and facility operators can find ease and peace of mind by partnering with a trusted, skilled refrigeration design/build contractor to evaluate their specific needs and help them choose the right solution.

WHAT ARE THE EFFICIENCY CONSIDERATIONS?

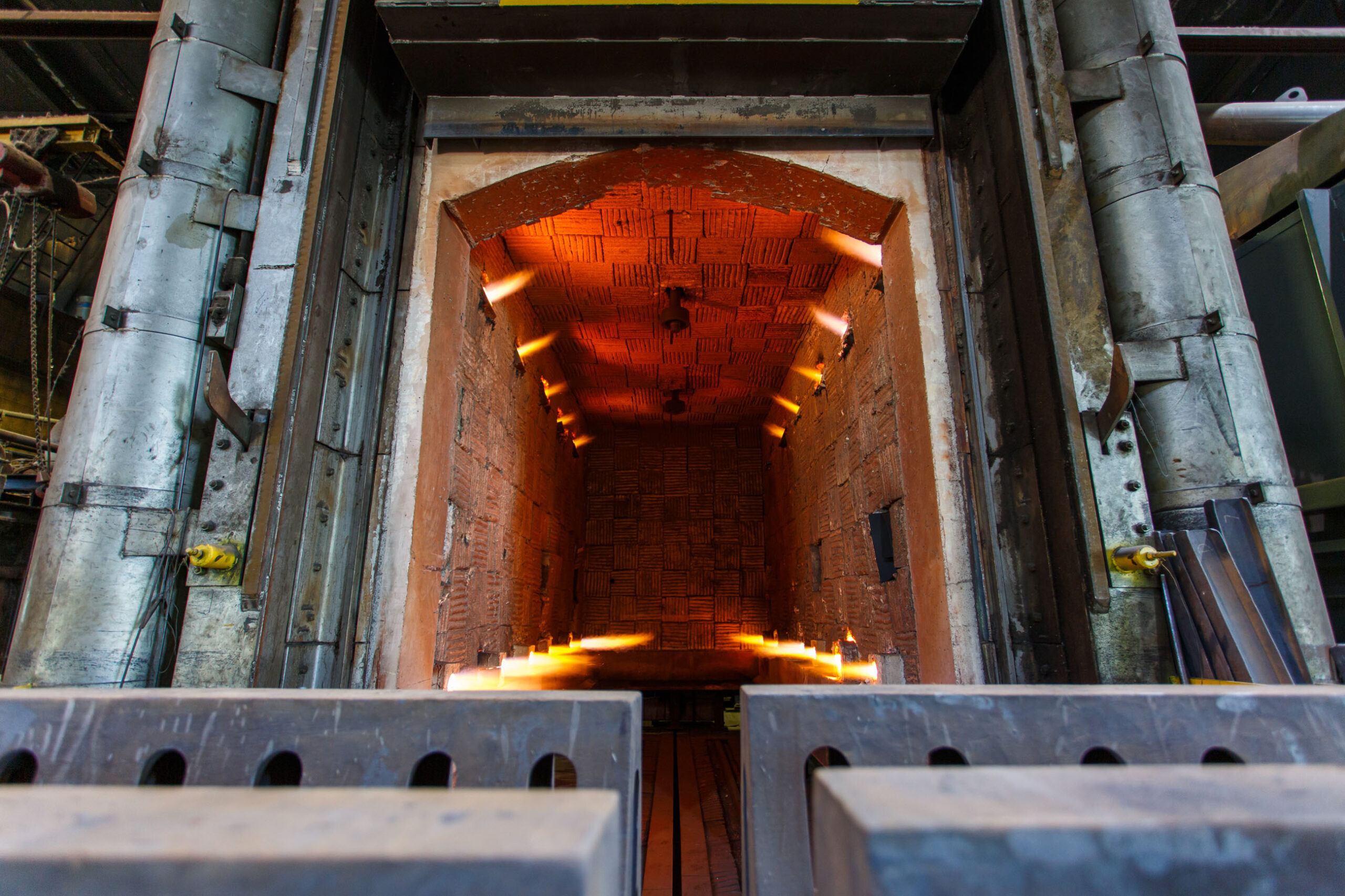

CO2, as a natural refrigerant, has carried with it efficiency concerns over a number of years. This is due to the relatively low temperatures at which CO2 enters the transcritical phase. This limits its effectiveness as a refrigerant, due to the inability to transfer heat efficiently, as it lacks the straightforward liquid to gas to liquid phase changes of traditional systems.

Recent advances in CO2 refrigeration technology, such as the use of ejectors and adiabatic condensers, make “transcritical” systems condense at “subcritical” levels a higher percentage of the time. This enables more frequent traditional, energy-efficient, refrigerant condensing on CO2 systems, elevating their efficiency. It is best to consult with a skilled refrigeration design/build contractor who is familiar with CO2 and ammonia, to create a comparative model based on your system requirements and the weather conditions in your geographical location.

A recently published article espoused the efficiency gains enabled by the installation of a NH3(ammonia)/ CO2 cascade system. In response to this article, a renowned industry expert asserted, “I have hereby provided the data to substantiate the claim that NH3 (ammonia)/CO2 cascade systems are generally less efficient than conventional two-stage R-717 (ammonia) systems and significantly less efficient than the centralized low-charge NH3 systems described…” Because of the significant difference in perspectives on this issue, and application-specific considerations, it is best to evaluate your system, your operating conditions and your environment with an experienced refrigeration professional.

WHAT ARE THE REGULATORY CONCERNS?

Due to its’ toxicity at concentrated levels, operation of ammonia systems include a variety of regulatory and safety concerns, that full-service providers, like Bassett Mechanical can help customers address through a consultative team of PSM/RMP professionals. There is a full suite of standards, published by the IIAR (a highly respected industry trade association), that has been adopted into code, regulating the design, installation, operation, and service of ammonia refrigeration systems. For ammonia systems, working with a design/build/service contractor familiar with IIAR Standards, OSHA’s PSM rules and EPA’s RMP regulations is a necessity.

It can be concluded that CO2 and ammonia are good, long-term, sustainable and “green” refrigerant choices, both being particularly efficient for low-temperature refrigeration.

CO2 currently does not have as high of a degree of regulation in its application as a refrigerant. Today, CO2 has reduced regulatory concerns relative to ammonia. It is important to note that due to the high-pressure requirements of CO2 systems (i.e. can have 1200 psi operation considered in lieu of ammonia’s 300 psi design conditions under certain conditions), new safety rules and standards are under development. With IIAR’s CO2 Standard expected to conclude its second public review in March 2020, change is coming quickly.

WHAT ARE THE OPERATIONAL CONCERNS?

CO2 industrial refrigeration systems, in application, are a recently renewed development. As such, one needs to consider a continuous relationship with a service provider that is familiar with this technology. There are not many full-service providers for CO2 systems available and having a trusted service partner becomes important.

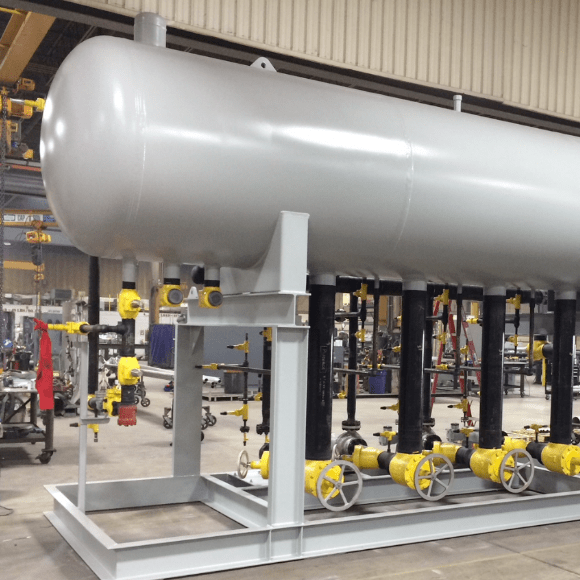

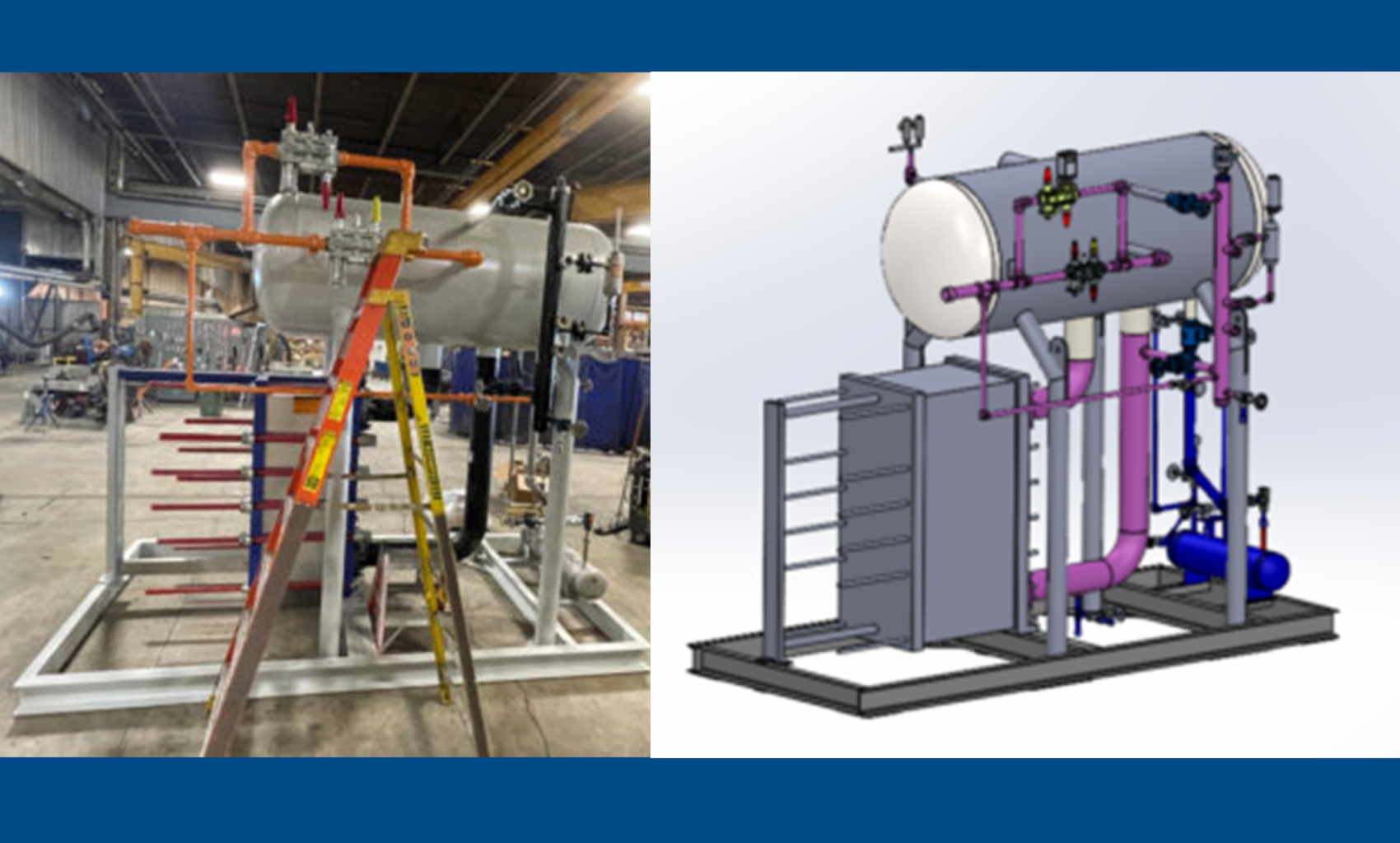

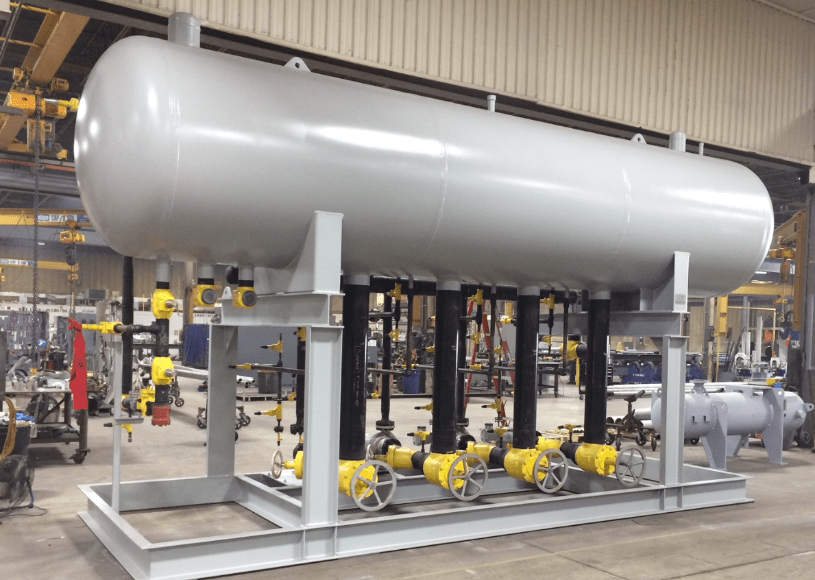

The high pressure of CO2 applications requires design engineers to detail unique equipment specifications. Equipment providers need to be up to date on CO2 requirements and standards for construction. As an example, Thermatech, a Bassett Mechanical company, produces pressure vessels and skids for CO2 applications, utilizing entirely different performance and material calculations, as required by ASME and CRN Code. As equipment and safety needs change, based upon refrigerant, it is paramount that suppliers are well-grounded in your individual application.

There is no easy button to help you decide if CO2, ammonia, or a combination CO2/ammonia system is right for your needs, but processors and facility operators can find ease and peace of mind by partnering with a trusted, skilled refrigeration design/build contractor to evaluate their specific needs and help them choose the right solution.

Bassett Mechanical is here to help. As a full-service provider, we specialize in the evaluation and design of unique refrigeration systems, and helping customers like you feel confident they made the best choice for their facility.

Still have questions about your refrigeration system? Check out our detailed guide or contact us anytime at info@bassettmechanical.com!