WE LISTEN

The customer needed to add 5 new packaging lines to their existing corporate production facility.

WE DISCOVER

To accomplish this goal, we installed 7 low-charge refrigeration packaged penthouse units and 14 penthouse and CPA air handlers on the rooftop of their new production facility. This would give the customer the capacity they needed to expand their production and meet their goals.

WE LOOK AHEAD

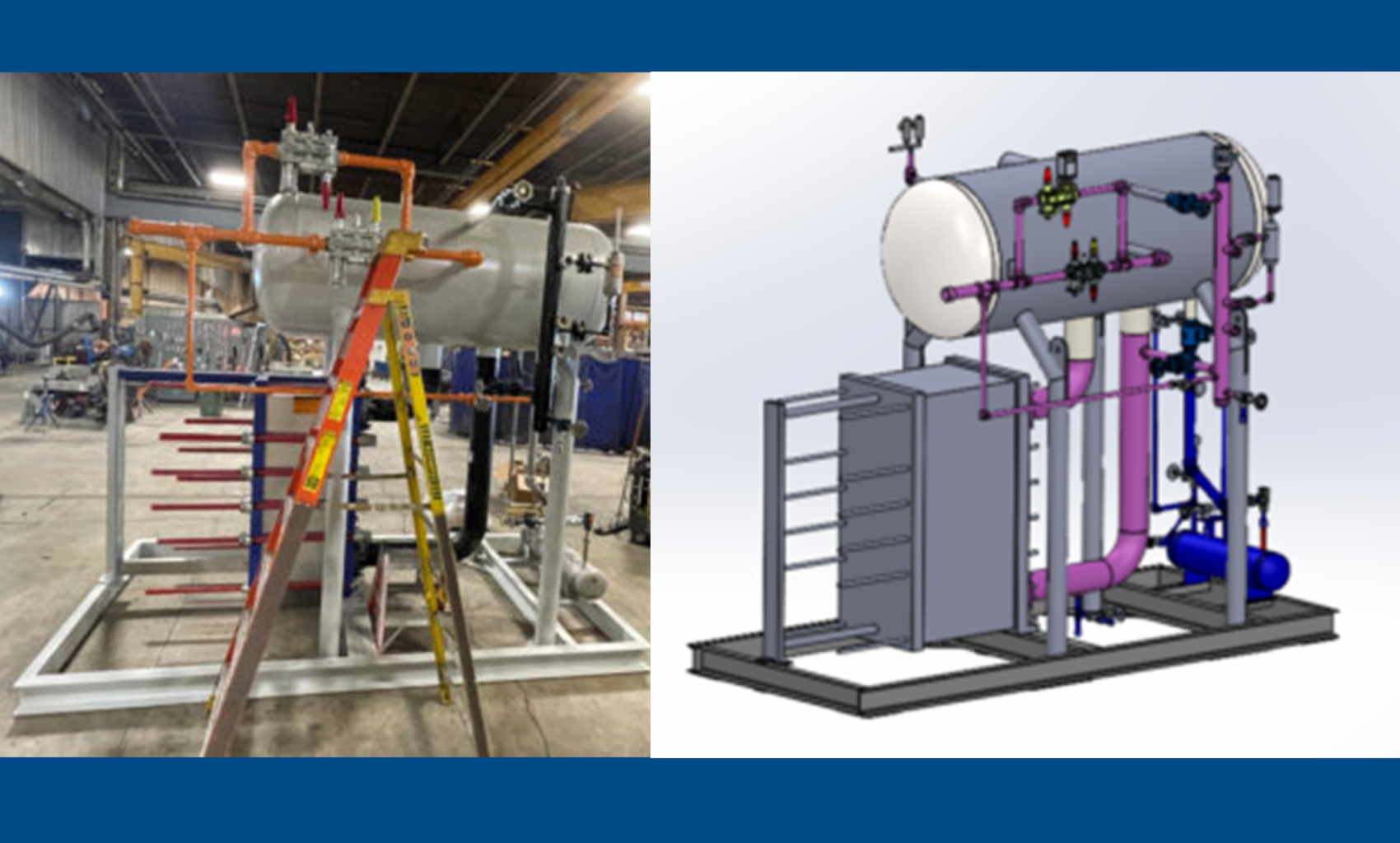

These low-charge refrigeration packaged penthouse units are an exciting new technology and a first-time installation for this customer. On typical ammonia refrigeration projects, you will find an engine room inside the facility with ammonia piping running out to the rooftop unit. These new packaged units include the engine room with the condenser unit on the rooftop. This safe and effective solution means minimal ammonia piping running on top of the facility’s roof and in turn, less ammonia on site.

WE DELIVER FULL-SERVICE SOLUTIONS

Our full-service solutions on this project included Industrial Refrigeration, Metal Fabrication, HVAC Controls, and Service.

WE ARE CREATING CUSTOMERS FOR LIFE®

This project took place for a customer facility located in Ohio. The customer was expanding its corporate production facility and was in need of 5 new packaging lines.

We were chosen for this project based on our strong relationships, reputation for independence, and the ability to provide quality solutions without oversite.

The placement of these units were 290 feet from the side of the building at their longest point. Typically a helicopter-type solution would be used for such a long distance, however, these 30,000 lb. units were placed with the use of a 500-ton crane. This crane had a boom that was 413 feet long and weighed 1 million lbs. The load required 474,000 lbs. of counterweights to be added. Truly a sight to see, this crane took 1 week to set up on-site and was transported on 30 semi-trucks.

Because the type of units being installed required minimal onsite rooftop piping to be run to and from the units, the installation time was minimal. Installation took approximately 2 days per unit; one day for placement of the unit and one day for the interconnecting piping. The entire project ultimately included 45 separate pieces of equipment to be placed and the project was completed in approximately 4 months.