Versatility. Customization. Endless Possibilities. As a provider of customized metal fabricating, Bassett Mechanical has the capabilities and expertise to fabricate just about anything, like a 90,000-pound mining dredge.

WE LISTEN:

A new customer – Ellicott Dredges – approached us and was looking for a metal fabrication contractor that could build a large stainless steel mining dredge. Due to the material specifications, Ellicott didn’t want to make this type of dredge in-house, so they reached out to a qualified, experienced contractor.

The project was a 90,000-pound, 18-foot-wide by 52-foot-long and 9-foot-tall 316L stainless steel dredge barge hull. The dredge was to be fully welded, passivated, and watertight.

WE DISCOVER:

Ellicott was looking for a contractor to perform the weld standards at the highest quality. Due to the stainless-steel material, heavy welding was needed, which was no problem for our more than 60 certified welders with more than 200 welding certifications. Unlike other contractors, we had the in-house capabilities to roll and form the length and thickness of stainless steel needed for the barge. We could also use our seam welder, an automated welding process, to provide a consistent and clean look.

Ellicott was looking for a contractor to perform the weld standards at the highest quality. Due to the stainless-steel material, heavy welding was needed, which was no problem for our more than 60 certified welders with more than 200 welding certifications. Unlike other contractors, we had the in-house capabilities to roll and form the length and thickness of stainless steel needed for the barge. We could also use our seam welder, an automated welding process, to provide a consistent and clean look.

The Material Test Report (MTR) was also crucial to the process for Ellicott because of the 316L stainless steel and the highly corrosive environment for the dredge’s end use. An MTR is a certified record of a material’s physical and chemical properties. These qualities are necessary for proper compliance, reporting, and application purposes. The process was not new to our team, as we have completed MTR reports for numerous customers upon request.

As the global leader in the design and build of dredges and dredge machinery, Ellicott worked closely with us throughout the project. Our project team made several trips to their facility to see the dredges built, talked through challenges they have seen, the type of quality they expect, and more.

“It was clear from our initial meetings that Bassett had the expertise in working with stainless steel and the reputation for quality. Through plant visits, they demonstrated capacity, capability, and strong organization,” said Duncan McTaggart, Director of Applications Engineering, Ellicott Dredges.

WE LOOK AHEAD:

During this process, we listened, discovered, and devised a plan to build the dredge in our manufacturing facility. We made sure to understand the scope of needs and familiarize ourselves with the challenges expected with a project of this magnitude.

This was a brand-new, never been done before project for Bassett Mechanical. The team spent several full days of preparation and research so we could deliver a product that met the quality, budget, and timeline of the customer.

“It was vital for us, and the project’s outcome that our team prepared for the project and discussed the tolerance of welds, weld sequence, and detailed production schedules. We were confident in our process and people and knew we would deliver a high-quality product Ellicott wouldn’t see anywhere else,” said Matt F., Local 18 General Fabrication Foreman at Bassett Mechanical.

WE DELIVER COMPLETE SOLUTIONS:

Our full-service solutions on this project included Metal Fabricating, Engineering, Quality, Sales, and Accounting.

WE ARE CREATING CUSTOMERS FOR LIFE®:

With the customer’s top priority of weld standards and quality on our minds, our team started assembling the dredge in our 268,000 sq. ft. manufacturing facility. We put together significant components of the dredge first. We started with the center hull section, then added the pontoons. We welded as much as possible, flipped it to weld the pieces on the bottom, and completed the rest of the welds in that position. We then passivated as much as possible before flipping it back over to install the remaining components and passivating the rest at the end. We worked with Ellicott monthly, in person and virtually, to discuss the progress and quality of the dredge.

With the customer’s top priority of weld standards and quality on our minds, our team started assembling the dredge in our 268,000 sq. ft. manufacturing facility. We put together significant components of the dredge first. We started with the center hull section, then added the pontoons. We welded as much as possible, flipped it to weld the pieces on the bottom, and completed the rest of the welds in that position. We then passivated as much as possible before flipping it back over to install the remaining components and passivating the rest at the end. We worked with Ellicott monthly, in person and virtually, to discuss the progress and quality of the dredge.

We overcame two challenges on the project: passivation of the stainless steel in a confined space and flipping the dredge. Passivation is a widely used metal finishing process to prevent corrosion. In stainless steel, the passivation process uses nitric acid or citric acid to remove free iron from the surface. The team was familiar with passivation; however, we were dealing with new chemicals, strategies, specific requirements, and limited space for this project. We worked with Ellicott, our quality control, and safety teams to create the correct and safest process for our team. We completed extensive research into what chemicals we could use and ensured the team had the proper respirators to achieve the passivation safely once they were in the dredge.

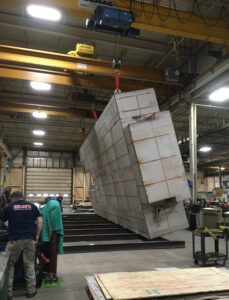

The other challenge was flipping the dredge – twice – which required a lot of prep and communication. At the time of the first flip, the dredge weighed 50,000 pounds. To flip it, because of its weight, we used three overhead cranes simultaneously, which we had never done before in our facility. We continued with the weld sequence and then repeated the process to flip it back. Prep and communication were important in the process because the team needed to be aware of the weight of the dredge to make sure it didn’t get too heavy to flip upside down.

weight, we used three overhead cranes simultaneously, which we had never done before in our facility. We continued with the weld sequence and then repeated the process to flip it back. Prep and communication were important in the process because the team needed to be aware of the weight of the dredge to make sure it didn’t get too heavy to flip upside down.

The dredge was fabricated in our facility over five months. Once the dredge passed the final inspection, and for it to be delivered to Ellicott, it needed to be loaded on a special-sized truck with extensive rigging and two cranes.

It was great working with the Bassett team. They have a strong team who asked smart questions, took pride in their work, and had attention to detail at every stage. – Duncan McTaggart, Director of Applications Engineering, Ellicott Dredges

Thanks to the close collaboration of our Bassett Mechanical teams, we created a Customer for Life in Ellicott as we continue to work with them on other projects.

Thanks to the close collaboration of our Bassett Mechanical teams, we created a Customer for Life in Ellicott as we continue to work with them on other projects.

Wherever your imagination leads you, we can help. We have the knowledge, qualifications, and full-service capabilities to bring your projects to life. Count on Bassett Mechanical for all your metal fabricating needs and let us help you achieve your goals.