As temperatures fluctuate and seasons change, HVAC systems become the heroes of comfort and climate control in our workplaces. Behind their reliable performance lies a critical factor often overlooked: preventative maintenance. Regular upkeep of HVAC systems isn’t just about ensuring cool air in summer and warmth in winter; it’s about optimizing energy efficiency, extending equipment lifespan, and safeguarding indoor air quality.

The Benefits of Regular HVAC Preventative Maintenance

In today’s fast-paced world, ensuring the efficiency and reliability of HVAC systems is more critical than ever. Here are some benefits of preventative maintenance:

Extended Equipment Lifespan

HVAC systems are significant investments, and like any other machinery, they require regular upkeep to operate at their best. Preventative maintenance helps identify and rectify minor issues before they become major problems. Regular check-ups ensure that components such as filters, coils, and fins are cleaned and function correctly, which can extend the equipment’s overall lifespan. This means fewer replacements and lower costs over time.

When HVAC equipment is dirty, it needs to work much harder to achieve the same level of cooling or heating. This is because dirt and debris block airflow, reduce heat exchange efficiency, and strain mechanical components. For instance, consider a scenario with an HVAC unit that has four compressors. If these compressors are dirty, their efficiency drops significantly. As a result, instead of running just one compressor to achieve the desired cooling, you might need to run three out of the four compressors. This consumes more energy and increases wear and tear on the equipment, leading to higher maintenance costs and a shorter lifespan.

Improved Energy Efficiency

Energy efficiency is a major concern for businesses aiming to reduce operational costs and their environmental footprint. A well-maintained HVAC system runs more efficiently, consuming less energy to achieve the same level of performance. This results in lower utility bills and contributes to a greener planet. Routine maintenance tasks like cleaning coils, replacing filters, and checking refrigerant levels can significantly improve the system’s efficiency.

One customer said, “Bassett did the maintenance and cleaning on our air handlers. We lowered the fan load needed, reducing our electrical bill by $1,400 per unit for the year. We reduced our chilled water flow by 60%, significantly reducing our energy bill. Bassett also pointed out some mechanical issues that were not taken care of, resulting in reduced equipment repairs and failures.”

Enhanced Comfort and Air Quality

An efficient HVAC system ensures consistent and reliable performance for many industries where maintaining specific temperature ranges is crucial. Preventative maintenance helps in avoiding sudden temperature fluctuations that could compromise product quality. Regular maintenance improves indoor air quality by removing dust, mold, and other contaminants from the system. This creates a healthier environment for both employees and customers.

Reduced Risk of Breakdowns

Unexpected HVAC failures can lead to costly downtime and disruptions in operations. Preventative maintenance involves thorough inspections and timely repairs, reducing the likelihood of unexpected breakdowns. Businesses can avoid the inconvenience and expense of emergency repairs or complete system failures by identifying and addressing potential issues early.

Cost Savings

While HVAC preventative maintenance involves an upfront cost, its savings far outweigh the expense. Regular maintenance helps identify and fix small problems before they escalate into more significant, costlier issues. Additionally, a well-maintained HVAC system operates more efficiently, lowering energy bills. Over time, these savings can add up, making preventative maintenance a smart financial decision.

Compliance with Regulations

For businesses in regulated industries like dairy, maintaining HVAC systems is not just about efficiency and cost savings; it’s also about compliance. Regulatory bodies often have stringent environmental control requirements to ensure product safety and quality. Regular maintenance ensures that HVAC systems meet these regulatory standards, helping businesses avoid fines and penalties.

Preparing Your HVAC Systems for Seasonal Changes: Essential Tips for Customers

Booking a yearly maintenance appointment with Bassett Mechanical ensures your HVAC systems are ready for seasonal changes, maintaining peak performance and efficiency year-round. As the seasons transition, schedule regular maintenance with a certified HVAC technician from Bassett Mechanical. This includes inspecting and cleaning components like coils, filters, and ductwork to ensure they are debris-free and operating efficiently.

Adjusting thermostat settings for seasonal temperature shifts helps optimize comfort and energy usage. Additionally, checking and sealing ducts, cleaning around outdoor units, and replacing air filters are simple yet effective steps to enhance system performance and indoor air quality. Staying proactive and addressing these maintenance tasks before each season will extend the lifespan of HVAC equipment, reduce energy costs, and ensure a comfortable indoor environment year-round.

How Often Should HVAC Preventative Maintenance Should Be Scheduled?

For optimal performance, schedule maintenance twice yearly—once for winter and once for summer.

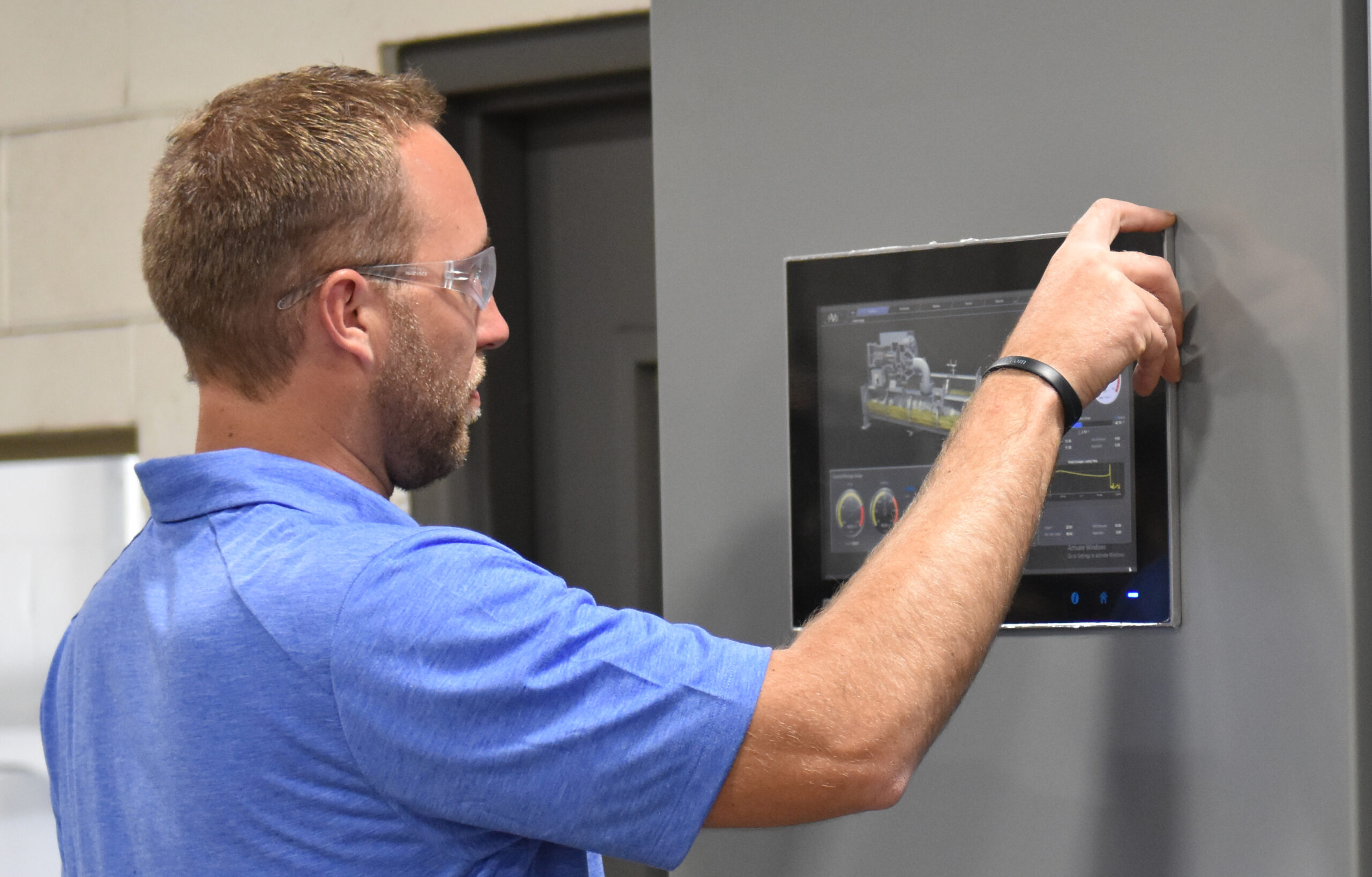

What to Expect from a Regular Preventative Maintenance Visit from Bassett Mechanical

When you schedule a visit from Bassett Mechanical, a technician with a professional appearance, the appropriate PPE and safety training, and all necessary tools will arrive at your location. Additionally, our technicians undergo a rigorous union HVAC Service Technician apprenticeship training program, and many hold associate degrees in HVAC. Our maintenance program offers much more than routine service. Upon arrival, our technicians will check in and address any questions. They will provide a detailed summary of the work performed and offer tips on preventative measures to avoid future issues.

All the information the technician shares and the work done will be recorded on their mobile device and uploaded to the customer portal. This portal includes scheduling dates and repair follow-ups to regular preventative maintenance checks and notes for future reference.

Understanding the Difference Between Preventative Maintenance and Reactive Maintenance

Preventative maintenance involves regularly inspecting equipment and addressing issues before they lead to failure. This allows for planning around people’s and process schedules and ordering parts to fix problems before they become critical. Reactive maintenance, however, means waiting for equipment to break before fixing it. This approach results in more downtime and unexpected issues, as problems are only addressed after they occur. Reactive maintenance often requires more time and money to get systems back up and running, with parts potentially taking weeks to arrive—by which time, it may be too late to prevent significant disruption.

Bassett Mechanical – Preventative Maintenance Experts

HVAC preventative maintenance is vital for businesses aiming to ensure operational efficiency, cost savings, and regulatory compliance. At Bassett Mechanical, we understand the critical role HVAC systems play in various industries, especially in dairy and food processing. Our team provides top-notch maintenance services to help businesses achieve optimal performance from their HVAC systems. Investing in regular maintenance not only extends the life of the equipment but also enhances energy efficiency, comfort, and air quality, ultimately contributing to the overall success and sustainability of the business.

For more information on our HVAC maintenance services, contact Bassett Mechanical today. Let us help you keep your systems running at their best.